Tower mill

Liaoning Dapeng Heavy Equipment Manufacturing Co., Ltd. provides you with one-stop service for mining wear-resistant machinery parts. Russian Russian Russian Russian

The PTM series metal mine tower mill independently designed and developed by Liaoning Dapeng Heavy can be widely used in the ultra-fine grinding of various ores and solid particles including gold, silver, copper, nickel, manganese, iron, zinc and lead. The whole machine and its parts have reasonable structure, small floor area, stable operation, low noise, long service life, considerable economic benefits, and the grinding effect reaches the domestic advanced level.

Key words:

Tower mill

Classification:

Tower mill

Hotline:

Tower mill

Tower mill principle and technical parameters

1. Tower mill

The PTM series metal mine tower mill independently designed and developed by Liaoning Dapeng Heavy can be widely used in the ultra-fine grinding of various ores and solid particles including gold, silver, copper, nickel, manganese, iron, zinc and lead. The whole machine and its parts have reasonable structure, small floor area, stable operation, low noise, long service life, considerable economic benefits, and the grinding effect reaches the domestic advanced level.

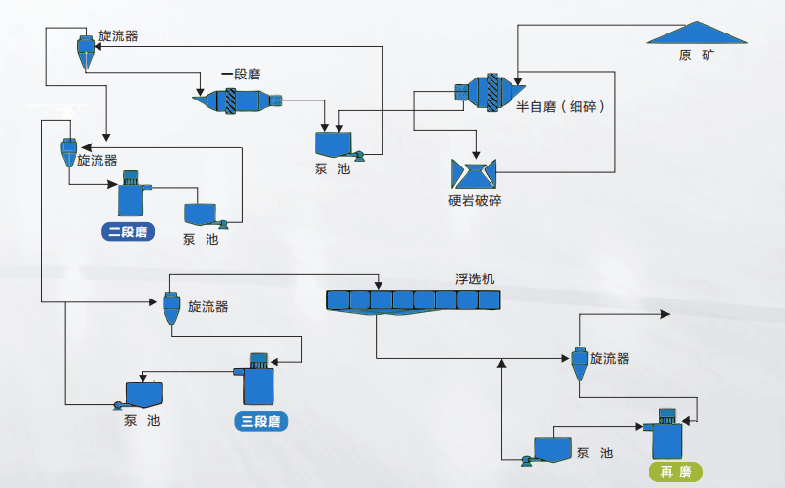

2. Working principle

In the process of low-speed rotating stirring screw operation, due to the effect of centrifugal force, gravity and friction force, the crushing medium and materials realize orderly movement cycle and the macro force is basically balanced. In the stirring screw, it is a spiral rise less than the lifting speed, and it is a spiral fall between the inner lining and the outer edge of the spiral. However, on the micro level, due to the non-uniformity of its force, the dynamic movement speed difference and force change are formed, resulting in the material being squeezed, ground and the combined effects of force breaking, micro-shearing and splitting between the materials. Conveying of qualified materials rises with the conveying medium and overflows from the upper part of the tower mill cylinder after internal classification.

The working principle of the tower mill is also shown in the following aspects: the enrichment between the crushing medium and the material is high, and the collision between the ball and the ball, the ball and the lining of the tower mill and the stirring spiral is few; The balance treatment of the force of the whole rotating part macroscopically makes the support system bear little force and the energy consumption of the bearing is also very small. Materials that meet the standards are always easier to reach the vicinity of the discharge outlet than materials that of the standards. The working principle of the tower mill, because the mixing speed of the tower mill is lower than that of other mixing mills, there is no relative movement of mechanical parts in the tower mill, and the stirring medium is orderly rolling, so the tower mill has a wider range of uses.

3. Characteristics of tower mill

Tower mill as a crushing equipment, in comparison, it has the following aspects of the final advantage: relying on to give mineral extrusion, grinding and internal classification, tower mill greatly reduce the system power. General use occasions can achieve energy saving more than 50%, special use occasions energy saving range is high, greatly reducing production costs. Relying on internal classification, the tower mill can easily process the ore into the required fineness of the product, and the fineness of the product is adjustable at 74 - 1 μm. A tower mill can control its production capacity and product particle size by adjusting the feeding amount and feeding particle size, which greatly improves the adaptability of the equipment. Tower mill for low-speed operation, is a high reliability, long service life of industrial equipment, the hardness of mineral materials, grinding ability to adapt, to achieve a large number of micron products production. As a kind of mixing mill, the size of tower mill is greatly reduced compared with horizontal ball mill. Compared with other mixing mills, the size of the main machine is slightly larger (due to low operating speed), but the auxiliary equipment is reduced. Tower mill overall equipment size is small and the whole system structure is simple. The tower mill and its micro-crushing system are continuous processes from feeding to product production. In the middle, a grading system can be added to form closed-circuit operation or open-circuit operation of direct product production. Both methods are easy to operate and convenient to manage, realizing continuous and stable industrial production. The tower mill can also carry out physical adsorption and chemical reaction of the product in the process of crushing the material. Low noise, low vibration, low heat. The tower mill crushing medium is an orderly movement, which reduces the ineffective collision and the ineffective power consumption, thereby reducing noise, vibration, and heating, and does not require a cooling device. The tower mill has a small area, no external rotating parts, and its internal force is fully balanced macroscopically. Its foundation only bears the net weight, so the foundation project is simple, the installation period is short, the equipment is safe and can be installed outdoors. On the basis of the above characteristics, the tower mill also has the following characteristics:

4. Design features

A unique auxiliary starting technology is designed to solve the problem of large starting load of this kind of equipment, and the rationalization of motor rate configuration and automatic electrical control are realized.

· The design of the excellent performance of the mixing screw device, can achieve a great increase in the service life of the mixing screw.

· Designed to support and reducer integrated transmission device, improve the mechanical efficiency of the tower mill, reduce the manufacturing cost and installation height of the tower mill.

· Designed a special mixing spiral installation, disassembly structure, making the replacement parts labor-saving, convenient and fast.

Technical advantages:

Greatly improve the grinding efficiency, the equipment covers a small area, low noise, saving energy consumption.

The secondary sedimentation and separation of the particle size into the mill, uniform control of the particle size distribution, improve the qualified particle size share of the product.

The inner wall wear-resistant lining plate is made of domestic magnetic rubber material, which can effectively prolong the service life.

The lower part of the cylinder adopts open door design, which is convenient for daily maintenance and overhaul.

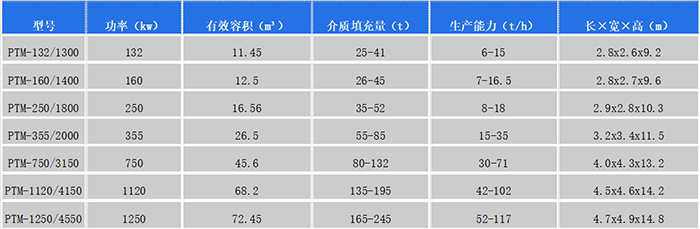

Technical parameters:

Remarks:The data in the table is only for selection reference, and the actual situation should be determined according to the nature of the processed material and the required product size or industrial test. At the same time, according to user needs, provide the model products not listed in the table, and the selection is more flexible and practical.

More products

High manganese steel has high tensile strength, plasticity and toughness and weak magnetism. Under the condition of high speed and heavy load, the working face will form a work hardening layer, which has good wear resistance. At the same time, it also has austenite. Even if the parts are worn to a very thin thickness, it can still withstand a large impact load without cracking, and will not cause secondary damage to the equipment itself.

The broken wall and rolling mortar wall of the cone on the market are generally made of high manganese steel.

Add lubricating oil during installation: when installing the crushing wall of the cone crusher, it is necessary to pour zinc alloy into the crushing wall. Before pouring zinc alloy, the crushing wall or the inner surface of the lining plate can be coated with a thin layer of lubricating oil, which can not only avoid moisture, but also increase the durability of the crushing wall and prolong the action time.

Broken wall, pricked wall is a very strong mechanical equipment, which can be carried out very well is to check its firmness before use, this will promote the efficiency of use more quickly.

Inquiry

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!